According to T. Townsend Brown, a capacitor tends to move in the direction of the positive electrode. Also, the higher the diectric constant (K) the better. Barium titanate (BaTiO3) has just such a high K dielectric.

Over the years I'd tried to make a high K dielectric using barium titanate by mixing it in powder form with a binder. Unfortunately the presence of the binder always resulted in a relatively low K, 27 being the highest I'd gotten as of June 12, 2010. See here for details of my attempts. The only solution seems to be to use sintering, a process I haven't tried yet.

So, at a friend's Wierd Science Gathering we tried making a barium titanate capacitor with large area by connecting a number of barium titanate doorknob capacitors in parallel, putting them on on a digital scale, and applying high voltage.

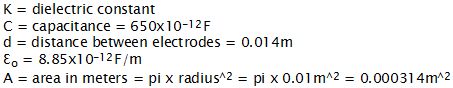

The first thing we did was to break apart a capacitor to see what it looked like inside. The length of the dielectric from electrode to electrode was 0.014m (meters). The radius was 0.01m.

|

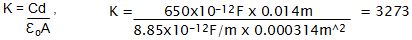

The capacitors were Sprague 650 picofarad, 18kVDC. 6930 and 6939 were also written on them. To calculate their dielectric constant, we started with the formula for the capacitance:

where:

and rearranged it to solve for the capacitance, K:

We tested one capacitor to find out the breakdown voltage. We gradually turned the voltage up to as high as 40kV with no breakdown of the dielectric. We also measured the capacitances of a few capacitors at random and got 582pF, 572pF, 575pF and 568pF.

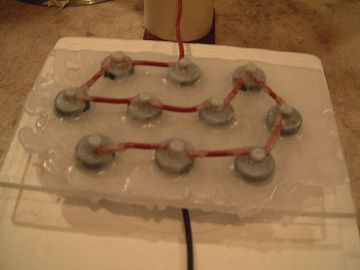

So then we made the paralleled capacitor by cutting ten holes in a sheet of plexiglass and epoxying a capacitor in each. We then wired the tops and bottom of the cacitors together and immersed the whole thing in wax to restrict breakdown around the capacitors. The following photos show the result.

|

|

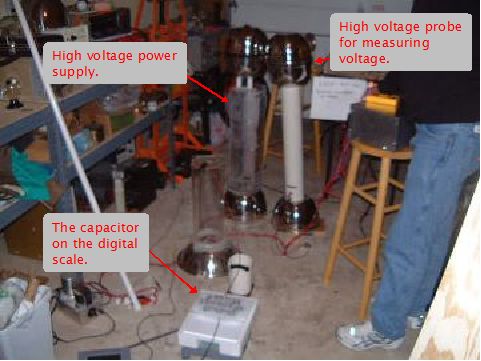

Finally we put it on a digital scale and gradually turned up the voltage. We measured the voltage using a high voltage probe. The following photo shows the setup.

|

We heard a snapping sound at around 59.5kV and could not get the voltage as high again afterwards. We measured the capacitance of the whole device and it was 5.661nF which is around 10 times the measured capacitance of a single capacitor as mentioned above. Since capacitances in parallel add, this was what we'd expect if none of the capacitors had broken down. We measured the individual capacitances and all were fine. What likely happened is that the breakdown occured around the outer surface of a capacitor from one electrode, through the wax and epoxy to the other electrode. We could find no evidence of it though.

At no time did the weight on the scale change.